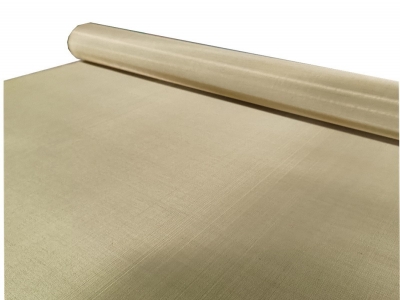

【 Name 】 Stainless Steel Filter Screen

【 Style 】 Plain Weave

【 Material 】 304/316 stainless steel

【 Mesh Size 】 2-400 mesh

【 Length 】 30 meters/roll

【 Width 】 1 -2 meters

【 Features 】 Uniform mesh/Smooth weave/Resistant to rust

【 Application 】 Mining/Chemical/Pharmaceutical/Petroleum/Metallurgical mineral filtration and screening, etc

Stainless Steel Oil Filtration Solutions: Why 304 and 316 Are Industry Game-Changers

Stainless steel filtration mesh is the unsung hero of efficient oil operations. Engineered to withstand punishing drilling environments while maintaining precision filtration, 304 and 316 alloys deliver unmatched performance where it matters most. Here’s how these materials elevate oil and gas processes worldwide.

Core Advantages: Why Stainless Steel Dominates Oil Filtration

Extreme corrosion resistance: Holds integrity in acidic, alkaline, and chloride-rich media common in drilling mud and produced water 59

Thermal resilience: Operates reliably from cryogenic temperatures up to 1500°F (815°C), ideal for high-heat extraction processes 4

Mechanical robustness: High tensile strength (900–1200 N/mm²) withstands intense vibration and abrasive slurries 810

Zero contamination: Non-reactive surface ensures filtered oil/petrochemical purity, critical for downstream quality 2

304 vs. 316: Matching Material to Operational Demands

| Property | 304 Stainless | 316 Stainless |

|---|

| Composition | 18% Cr, 8% Ni | 16-18% Cr, 10-14% Ni, 2-3% Mo 9 |

| Best for | Lower-cost acid/alkali exposure (e.g., onshore drilling mud) | Chloride-rich/severe corrosion zones (e.g., offshore, saltwater injection) 56 |

| Corrosion Resistance | Good in nitric acid ≤65%, organic acids | Superior against pitting, chlorides, sulfides, brine 19 |

| Cost Efficiency | More economical for standard applications | Higher upfront cost, but lower lifecycle expense in aggressive media |

Oil & Gas Applications: Where Performance Meets Innovation

Drilling Mud Filtration:

Three critical mesh types handle solids removal:

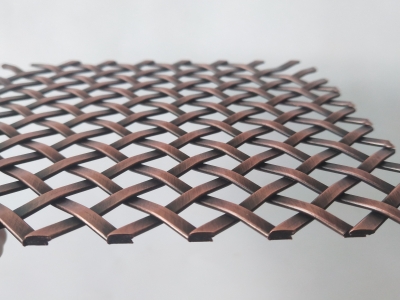

Frame Screens: Steel-framed multilayered mesh bonded with anticorrosive adhesives—stable under high vibration 10

Flat Panel Screens: 2–3 mesh layers laminated to perforated backing plates—maximizes durability and particle retention 10

Wave-type Screens: 125–150% larger effective area than flat panels—accelerates dewatering for high-volume slurry processing 10

Produced Water Treatment:

Surface-modified 304 mesh (e.g., fluorinated) achieves >90% oil separation efficiency with contact angles of 151°. Stays hydrophobic/oleophilic even after 100+ cycles 3.

Downhole & Pipeline Protection:

Woven mesh screens prevent sand/sediment ingress in injection wells and flow lines—resisting H₂S/CO₂ corrosion 7.

Material Selection Guidelines: Optimizing Lifecycle Value

Choose 304 when:

Handling general acids/alkalis (e.g., onshore drilling fluids)

Budget sensitivity exists (without compromising essential corrosion resistance)

Temperatures stay below 800°C 69

Choose 316 when:

Operating offshore, with seawater, or high-salinity fluids

Exposure to chlorides/sulfides risks pitting/crevice corrosion

Long-term asset integrity outweighs initial cost 59

Beyond Standard: Engineering for Next-Gen Efficiency

Modified Surface Mesh: Nano-roughness + hydrophobic coatings turn standard 304 into ultra-efficient oil-water separators 3

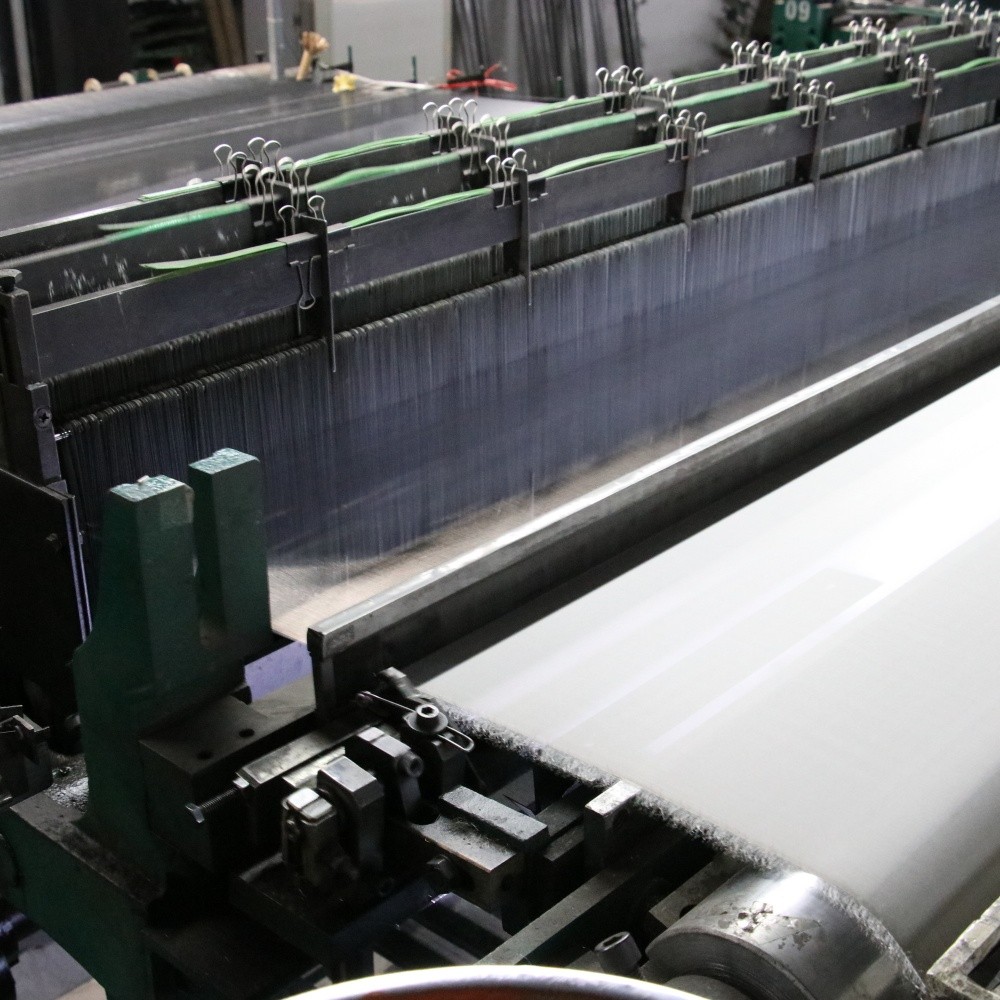

Precision Weaving: Tight tolerance control in plain, twill, or Dutch weaves meets ISO 9044 and ASTM E2016 specs 8

Custom Formats: Rolled, panel, or cassette designs for seamless retrofit into shakers, separators, and filters

Your Filtration, Perfected

For 15+ years, we’ve engineered stainless filtration solutions that outlast harsh oilfield environments. Our 304/316 meshes are certified to ASTM, ASME, and ISO standards—precisely woven, rigorously tested, and traceable from melt to final inspection.

Request a material comparison guide or discuss custom mesh specs → +86 15803114155

*Key specs assured: Tensile strength ≥900 N/mm², aperture tolerance ±3%, Mo content verification for 316 alloys*

.jpg)